Hypel™ imaging is a uniquely powerful method of delivering better images to your inspection processes. It solves common problems such as:

- Object features having poor focus

- Insufficient contrast

- Glare from shiny surfaces

- Noisy backgrounds interfering with foreground features

This new technology builds better images, enabling better inspection results.

Focus Enhancement

An object may have features on several planes, and/or the distance between the object and the lens may vary. When imaged under magnification, it is often impossible to capture an image having sharp focus. The laws of physics get in the way.

When purchased with a liquid lens, Hypel imaging can acquire images from multiple different focal planes. These images are then processed and combined, resulting in a single image having everything in focus.

Lens depth-of-field is no longer a problem.

Contrast Enhancement

Illuminating objects having shiny or unpredictable surfaces is normally a challenge. Consider the top film on a pudding cup. The glossy, undulating surface reflects light in arbitrary directions. Furthermore, the surface contains printed graphics, making it difficult to differentiate between dark print and a pinhole.

In this example, the Hypel imaging system rapidly changes the direction of light as eight images are captured. Hypel software extracts information from each of these images to build a composite image. The resulting composite image is not only free of all reflections, but the graphic print is made transparent. Only the defects — two small pinholes — remain. A simple blob tool from your favorite image processing platform will have no trouble finding these flaws.

Intensity Enhancement

All cameras have a limited dynamic range. Objects that have both bright and dark features can produce images having insufficient contrast. Put another way, imaging systems often cannot produce contrast between dark features, while also producing contrast between bright features.

The device shown here has a bright label and dark connectors. It is difficult to “see” into the USB connector without over-saturating the white label. The darker images better capture the label content and brushed aluminum surface, but the connector detail is lost. To overcome this, the Hypel imaging system acquires multiple images of the object, each captured using a different camera exposure duration. When combined together by Hypel software, the resulting composite image delivers sufficient contrast to inspect both the brightest and the darkest device features.

A camera's limited dynamic range is no longer a problem.

Still imaging with Old Tech?

Back in the day, we captured one image of each object, then crossed our fingers, hoping that image was good enough. Today, Hypel gains information by processing multiple images of an object, each captured under different conditions. It uses this information to build a composite image that is far superior to any single input image.

High Value

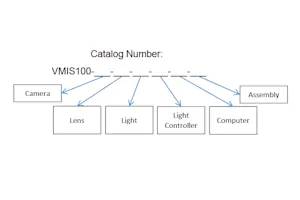

Hypel imaging systems have been pre-integrated to get you up and running fast. It includes a camera, lens, light, controller, processor, and cables appropriate for your project requirements. The software blends these disparate components into a ready-to-go solution, potentially eliminating weeks of engineering and programming effort.

Industrial Grade

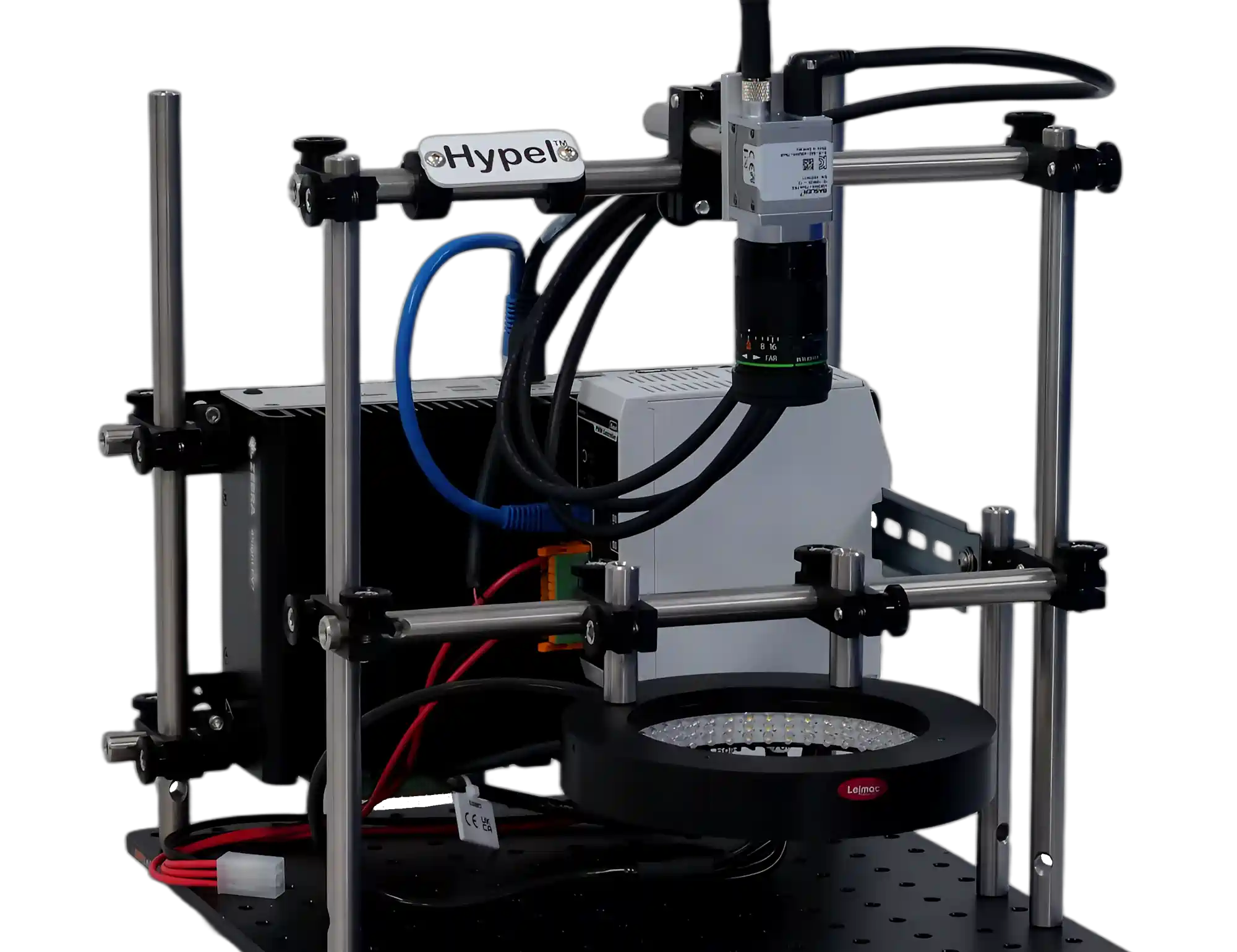

The Hypel imaging system can be provided as components for mounting on your machine, or pre-assembled on a breadboard for use in your lab. All components are industrial-grade and made by leading manufacturers.

Configurable

We’ll configure each system for your exact requirements. Chose from 3 cameras, 21 lenses, and 7 lights. Available with or without flowchart software for advanced image processing capabilities.

Hypel imaging systems are available either as component parts for installation on your machine, or pre-assembled ready for your lab.

Learn More

Please contact Machine Vision Store for additional information and a free project evaluation.